Welcome to the world of LED light strips, where illumination meets innovation. In recent years, these versatile lighting solutions have surged in popularity, revolutionizing the way we light up our homes, businesses, and even outdoor spaces. With their sleek design and energy-efficient features, LED light strips have become a go-to option for both interior decorators and DIY enthusiasts.

Definition and purpose of LED light strips

LED stands for Light Emitting Diode, which is a semiconductor device that emits light when an electric current passes through it. LED light strips consist of a series of individual LEDs mounted on a flexible circuit board.

These thin strips are usually self-adhesive on one side, making them incredibly easy to install in various settings. The primary purpose of LED light strips is to provide stylish and functional lighting solutions that can be easily customized to suit individual preferences.

Whether you want to create ambient lighting in your living room or highlight specific features in your kitchen, LED light strips offer endless possibilities. They can be used for accent lighting, task lighting, or even as primary sources of illumination.

Growing popularity and versatility of cut LED light strips

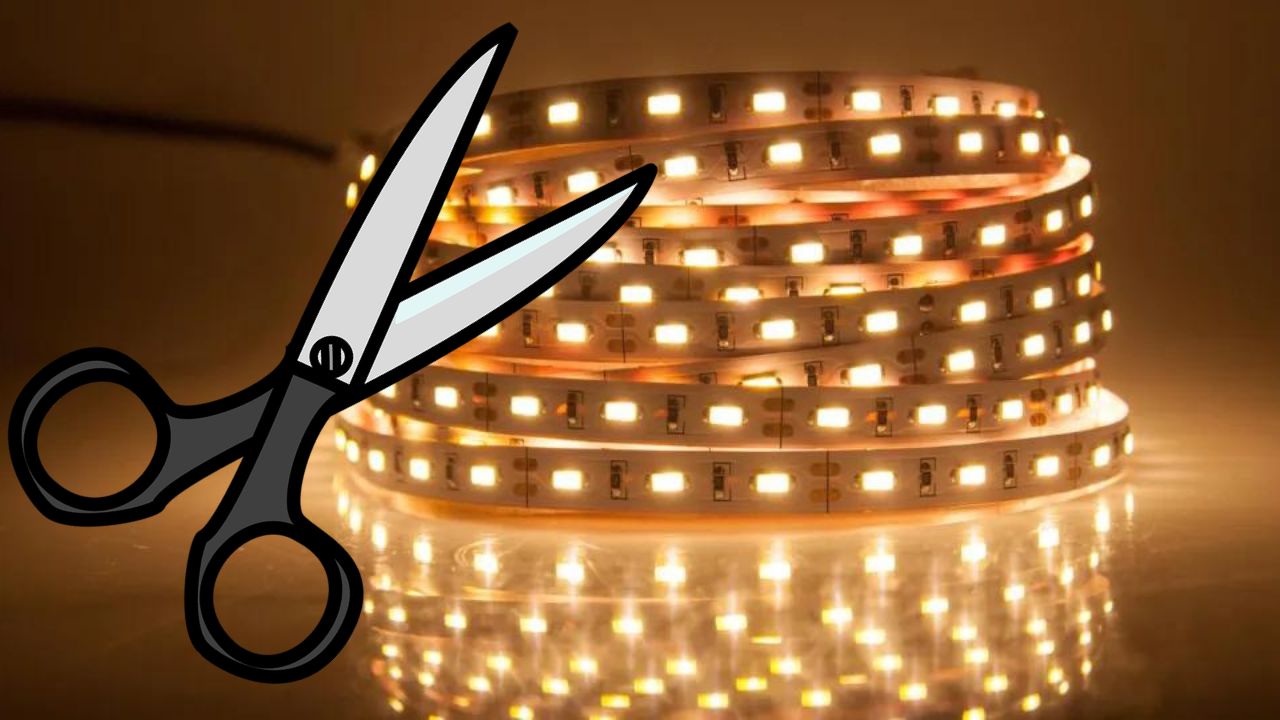

The demand for cut LED light strips has soared in recent years due to their exceptional versatility and adaptability. Unlike traditional lighting fixtures with fixed lengths, cut LED light strips can be trimmed at designated intervals without compromising functionality. This flexibility allows users to customize the length according to their specific needs and create seamless installations.

Cut LED light strips have permeated various domains such as interior design, architecture, event planning, and automotive styling due to their ability to transform spaces with vibrant colors or subtle hues. With an extensive range of colors available – from warm whites to vibrant RGB combinations – these versatile luminaires can evoke different moods or match any aesthetic preference.

Moreover, cut LED light strips have gained popularity among DIY enthusiasts who appreciate the simplicity of installation and the opportunity to showcase their creativity. Whether it’s for under-cabinet lighting, highlighting artwork, or creating stunning outdoor landscapes, cut LED light strips allow individuals to design and implement their lighting visions with ease.

Overview of Cut LED Light Strips

What are cut LED light strips?

Cut LED light strips, also known as LED tape lights or LED ribbon lights, are flexible lighting solutions that consist of small LEDs mounted on a narrow and flexible circuit board. These strips are usually sold in reels and can be easily cut into desired lengths to fit various applications.

The LEDs used in these strips emit bright light while consuming significantly less energy compared to traditional lighting options. Cut LED light strips have become increasingly popular due to their versatility, ease of installation, and ability to create stunning lighting effects.

Explanation of the structure and components

A typical cut LED light strip consists of several key components. The flexible circuit board acts as the base for mounting the LEDs and is often made from materials such as copper or fiberglass.

This design enables the strip to be easily bent or curved to fit around corners or irregular surfaces. The LEDs themselves are mounted at regular intervals along the circuit board.

These individual diodes emit light when an electric current passes through them. The diodes used in cut LED light strips are typically SMD (Surface Mounted Device) LEDs, which are small and energy-efficient.

To ensure proper functioning, these LEDS require a power source, which is provided by a driver or power supply unit (PSU). This PSU converts AC voltage from an electrical outlet into lower DC voltage suitable for powering the LEDs.

Different types and variations available in the market

The market offers a wide range of cut LED light strips with different specifications and features to suit various applications. One important variation is based on color temperature—ranging from warm white (2700K-3500K) for a cozy ambiance to cool white (5000K-6500K) for bright task lighting. Another essential aspect is brightness level, which is measured in lumens.

The higher the lumens, the brighter the light output. Cut LED light strips come in different brightness options, allowing users to choose based on their specific lighting needs.

Additionally, there are variations in terms of waterproofing and protection ratings, such as IP65 or IP67, making them suitable for both indoor and outdoor use. Some cut LED light strips also offer color-changing capabilities or even RGB (Red-Green-Blue) options that allow for a wide spectrum of colors to be emitted.

Moreover, certain cut LED light strips come with additional features like dimmers or remote control compatibility, enhancing user convenience and customization possibilities. Cut LED light strips are flexible lighting solutions that consist of small LEDs mounted on a narrow circuit board.

They can be easily cut into desired lengths and offer various features such as color temperature options, brightness levels, waterproofing ratings, and even color-changing capabilities. These versatile lighting solutions have gained popularity due to their energy efficiency and ability to create stunning lighting effects in a wide range of applications.

Advantages of Cut LED Light Strips

Energy Efficiency and Cost-Effectiveness

Cut LED light strips offer significant advantages in terms of energy efficiency and cost-effectiveness when compared to traditional lighting options. LED technology has revolutionized the lighting industry by providing a highly efficient alternative that consumes less energy while delivering bright illumination. Unlike incandescent or fluorescent bulbs, which waste a considerable amount of energy as heat, LEDs operate on a different principle, converting most of the electrical energy into light.

This increased efficiency translates into noticeable cost savings for users. With cut LED light strips, you can enjoy substantial reductions in electricity bills without compromising on lighting quality or brightness levels.

Additionally, their low power consumption allows for longer operating hours without worrying about exorbitant utility costs. This makes them an excellent choice for both residential and commercial applications.

Comparison with Traditional Lighting Options

When compared to traditional lighting options such as incandescent or fluorescent bulbs, cut LED light strips clearly outshine their counterparts in several aspects. First and foremost is their lifespan.

While incandescent bulbs typically last around 1,000 hours and fluorescents approximately 10,000 hours, cut LED light strips can endure up to an impressive 50,000 hours or more. The extended lifespan not only reduces the frequency of replacements but also minimizes maintenance costs over time.

Moreover, cut LED light strips are far more durable than traditional bulbs due to their solid-state construction that lacks delicate filaments or glass components susceptible to breakage. This durability factor makes them ideal for various applications where vibrations or shocks are common concerns.

Versatility in Design and Application

One of the greatest advantages of using cut LED light strips is their versatility in design and application possibilities. These strips come in various lengths and can be easily customized to fit any space or surface imaginatively. Due to their flexible nature, they can be bent, twisted, or curved without compromising their functionality or lighting performance.

This flexibility makes them ideal for adding accent lighting in both residential and commercial settings. Furthermore, cut LED light strips offer an extensive range of colors, brightness levels, and effects to suit diverse preferences and design requirements.

Whether you are aiming for a warm and cozy ambiance or a vibrant and dynamic atmosphere, LED strips can provide the perfect lighting solution. With options such as color-changing LEDs or dimmable strips, you have full control over the mood and aesthetics of any space.

Cut LED light strips bring forth numerous advantages that make them an attractive choice for lighting applications. Their energy efficiency ensures cost savings while reducing environmental impact.

Comparatively longer lifespans combined with durability result in reduced maintenance efforts and expenses. Their versatility in design and application allows for endless possibilities when it comes to illuminating spaces with style and creativity.

How to Cut LED Light Strips Properly?

Tools required for cutting LED light strips

When it comes to cutting LED light strips, having the right tools is essential to ensure a clean and precise job. You will need a pair of sharp scissors or a utility knife specifically designed for cutting through delicate materials.

These tools will allow you to make accurate cuts without causing any damage to the circuitry or the strip’s components. Additionally, if you plan on rejoining the cut ends of the strip, a soldering iron might be necessary.

Step-by-step guide on cutting LED light strips

1. Preparation: Measuring, planning, and marking the desired lengthBefore grabbing your tools and starting to cut, it’s crucial to measure and plan out the exact length you require for your project.

Using a measuring tape or ruler, carefully determine where you want to make your cut. Mark this point with a pencil or tape so that there is no room for error.

2. Cutting: Ensuring clean cuts without damaging the circuitryOnce you have marked the desired length, lay your LED light strip flat on a stable surface.

Take your sharp scissors or utility knife and position them perpendicular to the marked line. Apply steady pressure while making the cut in one fluid motion.

It’s vital to exercise caution during this process so that you don’t accidentally damage any of the electrical components within the strip. 3. Reconnection (if necessary): Soldering or using connectors

If you need to reconnect two ends of an LED light strip after cutting, there are two primary methods: soldering and using connectors. If you opt for soldering, make sure you have a soldering iron with a suitable wattage for working with delicate electronics.

Heat up your soldering iron and apply a small amount of solder to the exposed copper pads on both ends of the cut strips. Press them together and hold until the solder cools and solidifies, creating a secure connection.

Alternatively, you can use connectors specifically designed for joining LED light strip segments. These connectors usually feature clamps or pins that connect to the copper pads on each end of the strip, providing a reliable and safe connection without the need for soldering.

By following these steps carefully and using the appropriate tools, you can cut LED light strips accurately while maintaining their functionality. Remember to prioritize safety throughout the process to avoid any potential harm or damage.

Safety Precautions when Cutting LED Light Strips

Importance of safety measures while working with electricity

Working with electricity always requires caution and adherence to safety measures, and cutting LED light strips is no exception. Even though LED light strips operate at low voltage compared to traditional lighting options, it is crucial to take proper precautions.

One must understand that mishandling electrical components can lead to not only personal injury but also damage to the LED strip itself. First and foremost, before attempting any work on LED light strips, ensure that the power source is switched off or disconnected.

This prevents the risk of electrical shock and minimizes the chance of damaging the strip during cutting. Additionally, one should use insulated tools such as sharp scissors or a utility knife with non-conductive handles to avoid any accidental direct contact between conductive parts and live wires.

Moreover, it is vital to have a clear understanding of the specific instructions provided by the manufacturer regarding power supply requirements and installation procedures for a particular LED light strip model. Following these guidelines will help maintain personal safety throughout the cutting process.

Tips to prevent electrical shock or damage to the strip during cutting

To prevent electrical shock while cutting LED light strips, it is necessary never to cut or manipulate them while connected directly to a power source. Disconnecting from any power supply eliminates potential hazards associated with live wires.

When preparing for cutting, ensure you are working on a clean and dry surface – this helps minimize accidental slips or contact between exposed circuits and conductive materials that could lead to short-circuits or electrical hazards. When using scissors or a utility knife for cutting LED light strips, exercise caution not only in handling sharp objects but also in avoiding excessive pressure that may cause unintended damage.

Maintaining control over speed and force during cutting helps maintain accuracy while minimizing potential harm both for yourself and for the functionality of the LED strip. Furthermore, any exposed or cut ends of LED light strips should be properly insulated to avoid accidental contact with conductive materials or moisture.

This can be achieved by using electrical tape, heat shrink tubing, or specialized connectors designed for LED strip applications. Insulation not only protects against electrical shock but also preserves the longevity and reliability of the cut sections.

Remember, when it comes to working with electricity and cutting LED light strips, safety should always remain a top priority. Adhering to these precautions significantly reduces the risk of accidents and ensures that both you and your LED light strip remain unharmed during the cutting process.

Creative Applications for Cut LED Light Strips

Home Decor:

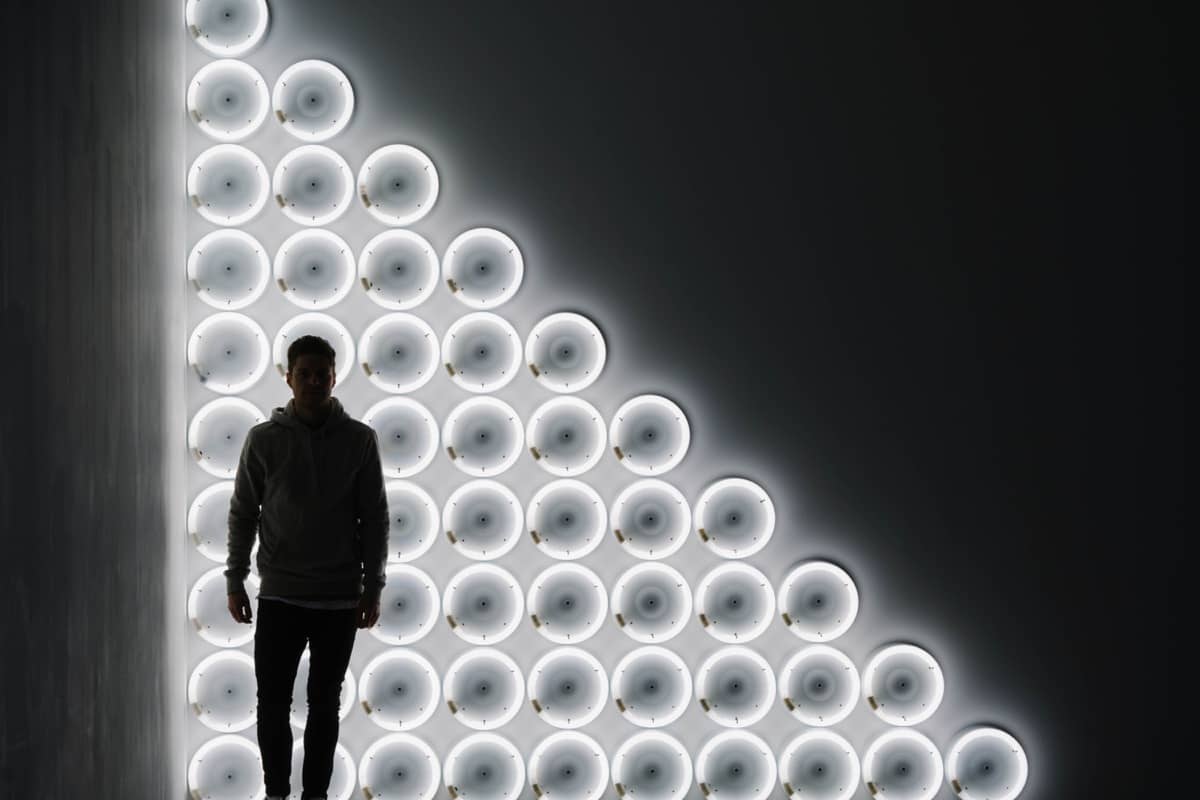

Cut LED light strips have revolutionized home decor by providing endless possibilities to enhance and transform living spaces. One of the most popular applications is accentuating architectural features such as cove lighting or under cabinet lighting. By strategically placing cut LED light strips along the edges of ceilings, walls, or cabinets, you can create a stunning visual effect that adds depth and dimension to any room.

Cove lighting, for example, can evoke a sense of elegance and sophistication by casting a soft ambient glow that bathes the walls from above. Similarly, under cabinet lighting not only illuminates countertops for practical purposes but also adds a touch of modernity and style to your kitchen or bathroom.

Another way to utilize cut LED light strips in home decor is by creating ambiance in bedrooms, living rooms, or entertainment areas. With their versatility in color options and brightness levels, these strips allow you to set the perfect mood for any occasion.

Imagine transforming your bedroom into a serene sanctuary with cool blue hues that promote relaxation and tranquility. Alternatively, adjust the brightness and color temperature in your living room to create a cozy atmosphere during movie nights or opt for vibrant colors during parties and gatherings to energize the space.

Conclusion:

Cut LED light strips offer an extraordinary range of creative possibilities in home decor while being energy-efficient and cost-effective at the same time. From accentuating architectural features to setting mood-enhancing ambiance in various living spaces, these versatile lighting solutions have become an essential component of modern interior design.

By embracing this innovative technology, homeowners can elevate their living spaces with captivating illumination that suits their personal style and preferences. With cut LED light strips becoming increasingly accessible and affordable, there has never been a better time to explore the endless design possibilities they offer.

So go ahead – unleash your creativity with cut LED light strips and transform your home into a beautifully illuminated haven that reflects your unique personality. Embrace the power of light and let it shape not only your living spaces but also uplift your spirits!